Vertical assets such as communications, tall buildings, or water towers are difficult and dangerous to inspect. For this reason, UAV technology is quickly becoming the preferred method of vertical asset inspection.

Three primary reasons UAV inspections are becoming prominent are safety, time savings, and superior documentation; these are just some of the immediate benefits we see using drones to complete vertical inspections. Other, not so obvious advantages include: change detection, automated computer identification of maintenance deficiencies, and large scale trend analysis across asset networks.

Time Savings and Risk Reduction

Physical inspection of towers is dangerous and time consuming, but drone inspection removes the danger to personnel while saving time. By collecting detailed information of each tower, we not only create a comprehensive digital twin of the asset, but also remove the need for physical inspection when deficiencies are not present. Time savings are great, but the safety value of not sending personnel into hazardous environments unnecessarily is enormous in reducing risk. The best way to mitigate risk is to avoid dangerous situations altogether. Unmanned systems are easily able to inspect even the highest towers, removing the risk of physical inspection.

Documentation

Using high resolution sensor payloads, modern UAVs consistently and accurately complete complex flight routines, providing imagery that is comprehensive and extremely detailed. This UAV imagery is of sufficient quality to inspect even the smallest fasteners, brackets, and cables. Producing a comprehensive digital twin, every tower inspection creates an asset record that is both repeatable and auditable. Tasks including corrosion monitoring and change detection are completed by comparing historic scans to current inspection data.

Common Use of UAV for Vertical Inspection

- Communications; Cellular, Navigation, and Radio

- Tower Structure and Post Configuration Modeling

- Panel Antenna and Box Inventory

- Corrosion Monitoring

- Electric Transmission and Distribution

- Crossbar, Insulator, and Dampener Inspection

- Structural Evaluation

- Nesting Bird Mitigation

- Substation Inspection

- Oil and Gas

- Flare tower

- IR/Thermal Imaging

- Offshore Platform

- Tank and Pipeline Corrosion Assessment

- Compressor Station Inspection

- Flare tower

- Utilities and Public Works

- Bridge, Dam, and Lighthouse Inspections

- HVAC and Commercial Roof evaluation

- Water Tower Inspection

Scanning Techniques for Creating an Accurate Digital Twin

By performing multiple parallel flight patterns near each asset, we collect sufficient information to create a 3D reconstruction. This not only allows us to inventory tower attachments, but also provide detailed information regarding the position, orientation, and condition on every piece of that asset.

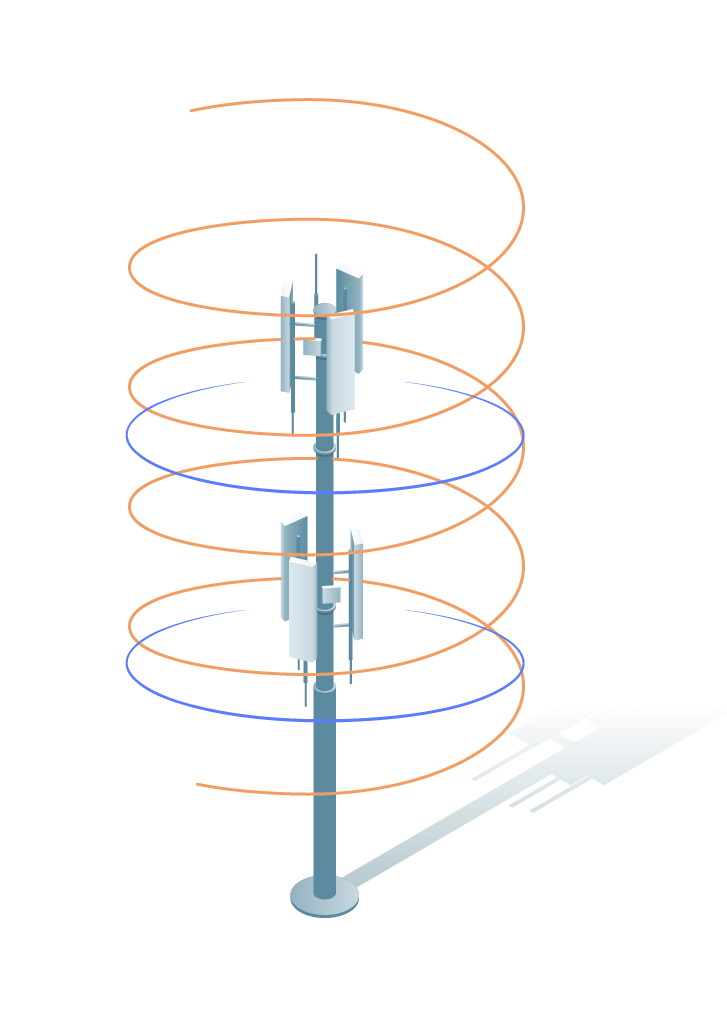

Automated Flight Routines

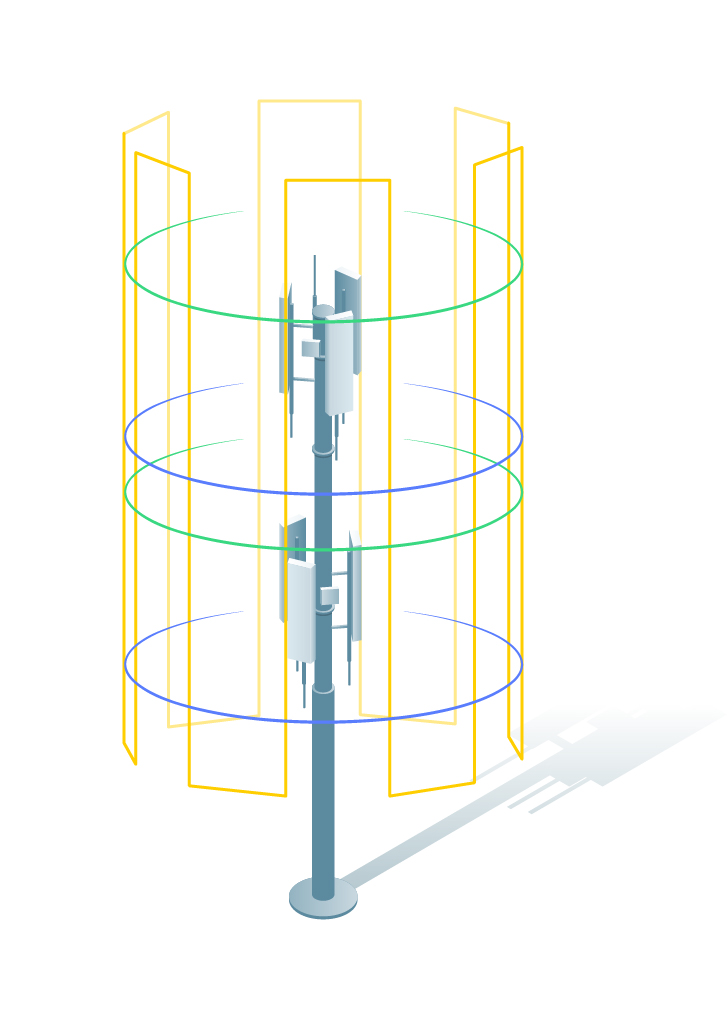

There are two main types of automated flight routines used to capture vertical assets: helix and cylinder. Helix is the most efficient way to collect free standing assets. Orbiting around the target in a circular pattern and reducing altitude slightly on every rotation, the helix pattern allows for a single smooth flight line that reduces scan time and improves coverage. Free standing means a structure with no supporting wires, arms or framework. In the case of assets supported by guy wires or other framework that may interfere with a helix flight pattern, the cylinder routine must be used.

Cylinder flight patterns allow for a single vertical flight line to collect data. While this is not the ideal scan pattern, cylinder scans can still provide the data required to create accurate digital twins. Keep in mind that since the cylinder pattern is limited by the physical constraints of the asset structure, it may be necessary to supplement your scan with additional data points outside of the flight routine. This can be done in manual flight mode by making sure the gimbal angle is low enough to capture only the asset of interest. If the gimbal is not tilted below the horizon line, error could be introduced by the presence of sky in the photos. If photos containing the sky are inadvertently captured, do not worry – these can simply be removed from the dataset during post processing.

Helix and Cylinder Flight Missions Respectively, Photo Credit: Pix4D

Manual Flight

Complex or asymmetrical vertical assets may require manually controlled flight; for this, a skilled pilot is required. The best technique for free flight is “timed capture,” in which the camera is set to shoot on a defined interval and allows the pilot to focus on the flight rather than the camera. This method increases the likelihood of unintentional image capture, but as mentioned above, we simply review and remove any unwanted images during post processing. Manual flight should mimic the overlap found in automated routines while avoiding any structures that may pose a threat to UAV equipment.

It is important to note that obstacle avoidance sensors do not reliably detect power lines and supporting cables. For this reason, a skilled pilot is required to complete these tasks.

Overlap

When using automated routines, the flight controller overlap parameters should be set to a minimum of seventy percent. If the structure being scanned is especially complex, the overlap increases to eighty percent. If there are complicated antenna nests or arm structures present, it may be necessary to complete additional orbits around those equipment to produce an accurate model. Remember, more information is better when creating digital twins. You can always remove data prior to processing, but it is much more difficult to go back into the field and rescan an asset if insufficient data were collected initially.

Vertical asset scans may seem intimidating due to their complexity, but with practice and patience you can create accurate digital twins much quicker and more comprehensive than traditional inspections.

Examples

Cell Tower Digital Twin

Cell Tower Video

If you have a vertical asset and need it inspected, we would be happy to help. Reach out to us at connect@geo-jobe for a quote!